Purge Solutions: Reliable Safety for Hazardous Locations

Purge Solutions’ purge and pressurization systems protect hazardous location equipment in industries like oil and gas, chemical, and pharmaceutical. These systems keep control panels and electrical gear safe in explosive environments by creating a clean, pressurized atmosphere inside enclosures.

All products meet global safety standards, including NFPA 496, ATEX, and IECEx. They are approved for use in Class I, II, and III Divisions. Purge Solutions offers customization options, including LED indicators, alarm relays, and interface features that make monitoring easier.

These systems reduce the risk of ignition and help facilities meet safety rules without complicating operations. They’re reliable and easy to install and maintain.

Trusted Systems for Hazardous Environments

Purge Solutions systems protect devices like analyzers, control panels, and sensors by keeping flammable gases out. There are three main types of purge and pressurization systems, each made for different levels of risk in hazardous areas.

- Z Purge System: Division 2 or Zone 2. Maintains pressure inside the enclosure to stop gas from entering.

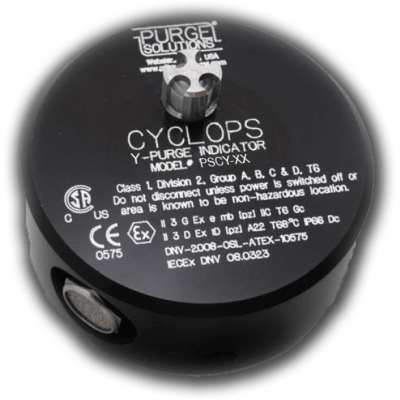

- Y Purge System: Division 1 or Zone 1. Removes hazardous gases first, then keeps pressure inside to make it safe for standard equipment.

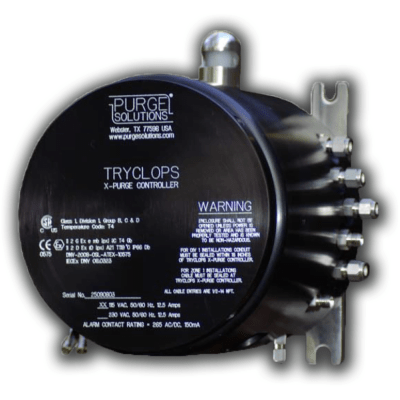

- X Purge System: Division 1 or Zone 1. Goes further than the Y purge system by fully declassifying the enclosure through constant overpressure.

All systems are approved by UL, cULus, and CSA, making them trusted across many industries. Whether you’re protecting electronics in a refinery or a lab, Purge Solutions helps reduce explosion risk and keep operations running safely.

Frequently Asked Questions

What is the Z Purge system?

The Z Purge system protects hazardous location equipment in Division 2 or Zone 2 areas by creating and maintaining a positive pressure inside an enclosure. This pressure displaces flammable gases or vapors with clean air or inert gas, ensuring the equipment stays in a safe environment.

Z Purge systems from Purge Solutions are built to meet NFPA 496 purge system standards. They include helpful features like alarm relays and LED status indicators to provide assurance that the system is working properly. This makes the Z Purge system an ideal choice for protecting sensitive electronics in less hazardous but still potentially explosive environments.

What is the Y Purge system?

The Y Purge system is designed for Division 1 or Zone 1 locations, where conditions are more dangerous. It allows general-purpose equipment to be installed after purging the enclosure of flammable gases and continuing with pressurization. Once purged, the equipment inside the enclosure is considered safe for operation.

Purge Solutions offers Y systems that include timers, flow controls, and monitoring features to maintain compliance with safety standards. As a trusted part of many purge and pressurization systems, the Y Purge system helps transition uncertified devices into hazardous areas while minimizing risk.

What is the X Purge system?

The X Purge system is the most advanced option for Division 1 or Zone 1 environments. It creates a non-hazardous internal space by completely displacing combustible gases and maintaining overpressure within the enclosure. This allows standard hazardous location equipment to be used in areas where explosions could occur.

Certified to NFPA 496 purge system standards and UL listed, the X Purge system includes automatic shutdown functions and fault alarms to ensure the highest level of protection. Purge Solutions has engineered these systems to deliver safety, ease of use, and long-term reliability in extreme conditions.