Exloc is proud to partner with Newson Gale, a global leader in static grounding and bonding systems. Their technology helps reduce ignition risks in combustible environments using equipment designed to meet global safety standards.

From drum filling to truck loading, Newson Gale products help protect people, facilities, and assets from electrostatic discharge in flammable atmospheres.

Why Static Control Matters

Operations like drum filling, tanker loading, and blending create static charges that can ignite flammable gases, vapors, or dusts. Without proper controls, these charges become a hidden ignition source.

Newson Gale static grounding systems reduce this risk by controlling and dissipating static electricity. For any plant handling flammables, managing static buildup is a critical part of safety planning.

Newson Gale’s Flagship Systems

Newson Gale offers a line of trusted systems that cover a wide range of static grounding and static bonding solutions. Each product is designed to support hazardous area static control in line with global codes and practices.

-

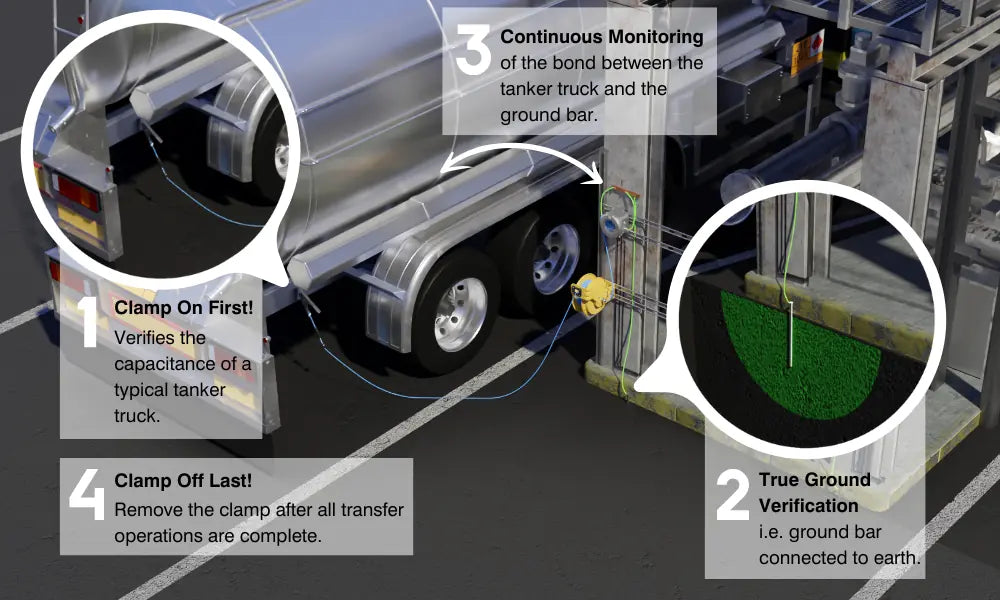

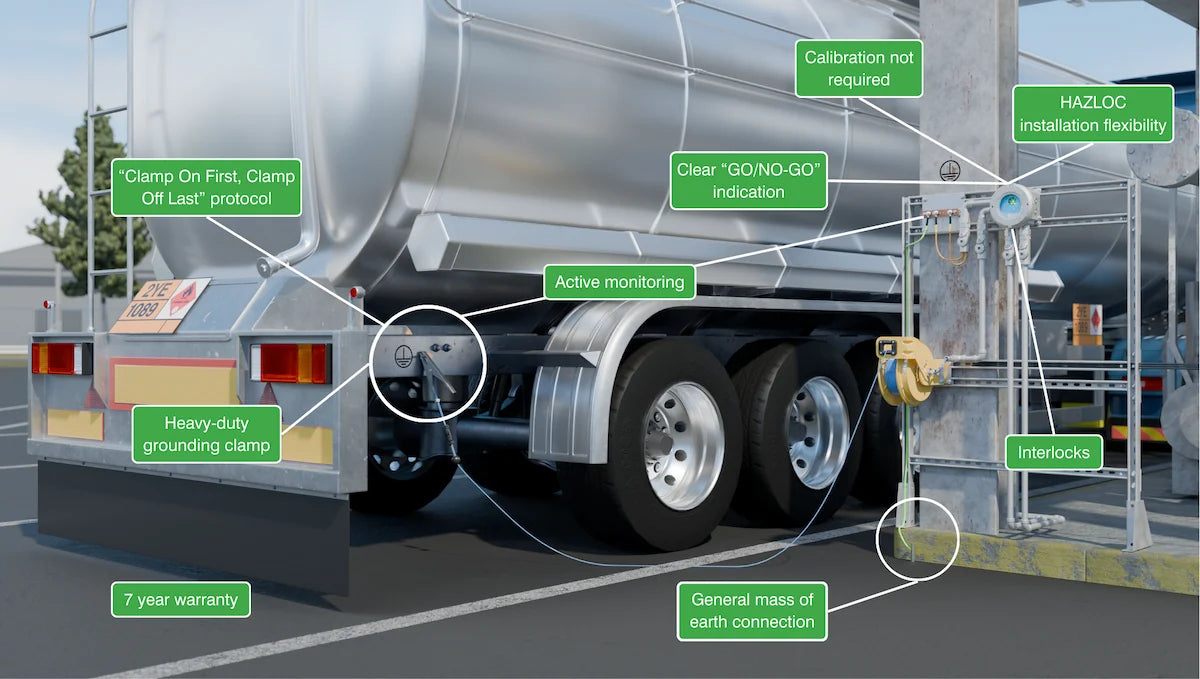

Earth-Rite II RTR: A monitored tanker truck grounding system that checks for a verified bond before and during transfer.

-

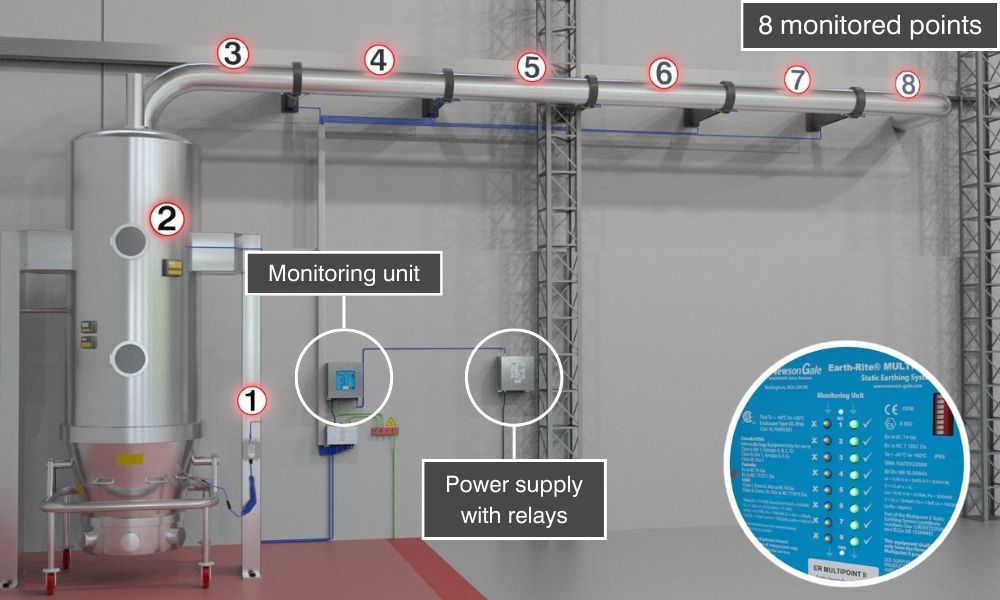

Earth-Rite MULTIPOINT II: Supports up to eight grounding points at once for larger or multi-vessel setups.

-

Clamps and Cables: Heavy-duty clamps with sharp teeth ensure solid connections through paint, rust, or coatings.

-

Grounding Reels: Retractable reels offer quick, reliable grounding for mobile or temporary equipment.

Frequently Asked Questions

What kinds of ignition risks does Newson Gale static grounding help control in hazardous areas, and why isn’t basic earthing hardware enough for many plants?

Static discharge can ignite flammable gases, vapors, or dusts. Basic earthing hardware doesn’t confirm a good connection. Newson Gale static grounding systems monitor and verify grounding to prevent sparks and reduce ignition risks.

How do Newson Gale static bonding solutions work in typical applications like drum filling, tanker truck loading, and mixing or blending operations?

These activities build up static. Newson Gale systems ground the equipment using clamps and cables, then verify the connection. Some systems stop product flow if grounding is lost.

What industry standards and recommended practices (such as NFPA 77 or IEC/ATEX guidance) do Newson Gale systems help facilities align with?

Newson Gale static grounding and bonding solutions support compliance with NFPA 77, IEC 60079-32-1, and ATEX guidelines by providing verified, monitored static control in hazardous areas.

When should a site consider upgrading from a single grounding point or simple clamp to a monitored system or a tanker truck grounding system like Earth-Rite II RTR?

Upgrade when handling flammable materials in classified zones, loading trucks, or needing real-time monitoring. The Earth-Rite II RTR tanker truck grounding system gives added safety and alerts for failed connections.

How does the Earth-Rite MULTIPOINT II differ from other Newson Gale products, and in what situations is multipoint hazardous area static control the better choice?

The Earth-Rite MULTIPOINT II monitors up to eight points at once. It’s best for sites with multiple vessels, reactors, or mixers that need simultaneous hazardous area static control.