- Description

- Technical Data

- Resources

Description

GET A QUOTE – For business orders requiring a written quote or for volume pricing please request a quote.

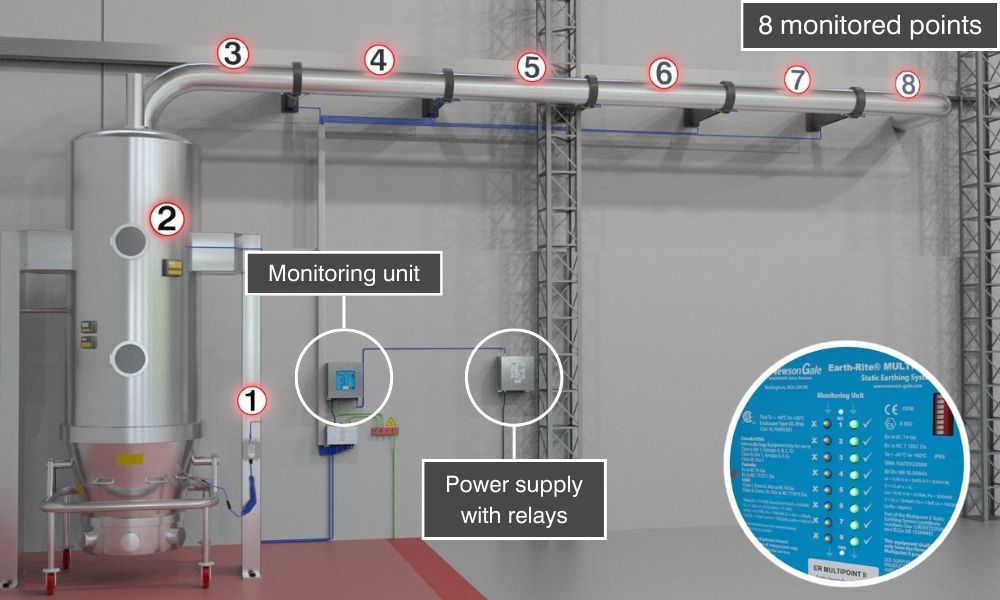

The Newson Gale Earth-Rite MULTIPOINT II is a multipoint static grounding system that monitors up to eight equipment connections at once. It helps reduce electrostatic ignition risks by confirming a secure ground path for each channel. This hazardous location grounding monitor uses visual indicators and system outputs to keep operators informed and processes safe.

This system supports industrial sites where multiple pieces of equipment must be grounded during operations. It provides consistent static ground monitoring across mixers, hoppers, drums, or vessels located in hazardous areas.

Eight Channels, Clear Feedback, Flexible Integration

The Earth-Rite MULTIPOINT II monitors eight independent channels for proper grounding. Each connection point checks for a resistance below 10 ohms, confirming a low-resistance path to ground. The system is certified for use in Zone 0, Zone 1, and Zone 2 areas, and it meets IEC and NEC hazardous location standards.

The system features clear, simple LED indicators for status information. A green LED confirms the channel is safe, while a red LED indicates a problem that needs attention.

The multipoint static grounding system can link to control equipment. Each output can interlock with pumps, valves, or PLCs, stopping operations if any connection is unsafe. Remote indicators can mirror LED signals to other work areas, which ensures grounding status is visible and integrated into safety logic.

Frequently Asked Questions

What is the Newson Gale Earth-Rite MULTIPOINT II, and how does a multipoint static grounding system differ from single-point grounding solutions?

The Earth-Rite MULTIPOINT II checks grounding for eight pieces of equipment. A single-point system only monitors one. This multipoint static grounding system is better for sites with many vessels, improving safety and saving time.

How many channels does the Earth-Rite MULTIPOINT II provide, and what kinds of equipment (pipes, hoppers, dryers, mixers) can each hazardous location grounding monitor channel be connected to?

It provides eight channels. Each hazardous location grounding monitor input can connect to conductive items like mixers, dryers, hoppers, pipes, or tanks used in flammable processing.

How does the system’s static ground monitoring work in practice, including resistance thresholds, LED indications, and feedback from remote indicator stations?

Each channel runs a continuous check for less than 10 ohms of resistance. Green LEDs show good grounding, while red LEDs show a fault. Optional remote stations repeat these signals in other locations. Static ground monitoring happens in real time for every connection.

In what ways can the Earth-Rite MULTIPOINT II be integrated with pumps, valves, or PLCs so process equipment only runs when all grounding conditions are satisfied?

The system has outputs that can stop pumps or valves if grounding is not confirmed. It can connect to PLCs to ensure the process only runs when all eight points are safe.

What installation, commissioning, and periodic testing steps are recommended to keep the Earth-Rite MULTIPOINT II compliant and reliable over the long term?

Use proper ground points during installation. At startup, verify resistance and test each LED. Recheck grounding and LED function as part of regular inspections to keep the system reliable.

Technical Data

| Earth-Rite MULTIPOINT II Basic Specification | |

|---|---|

| Specification | Details |

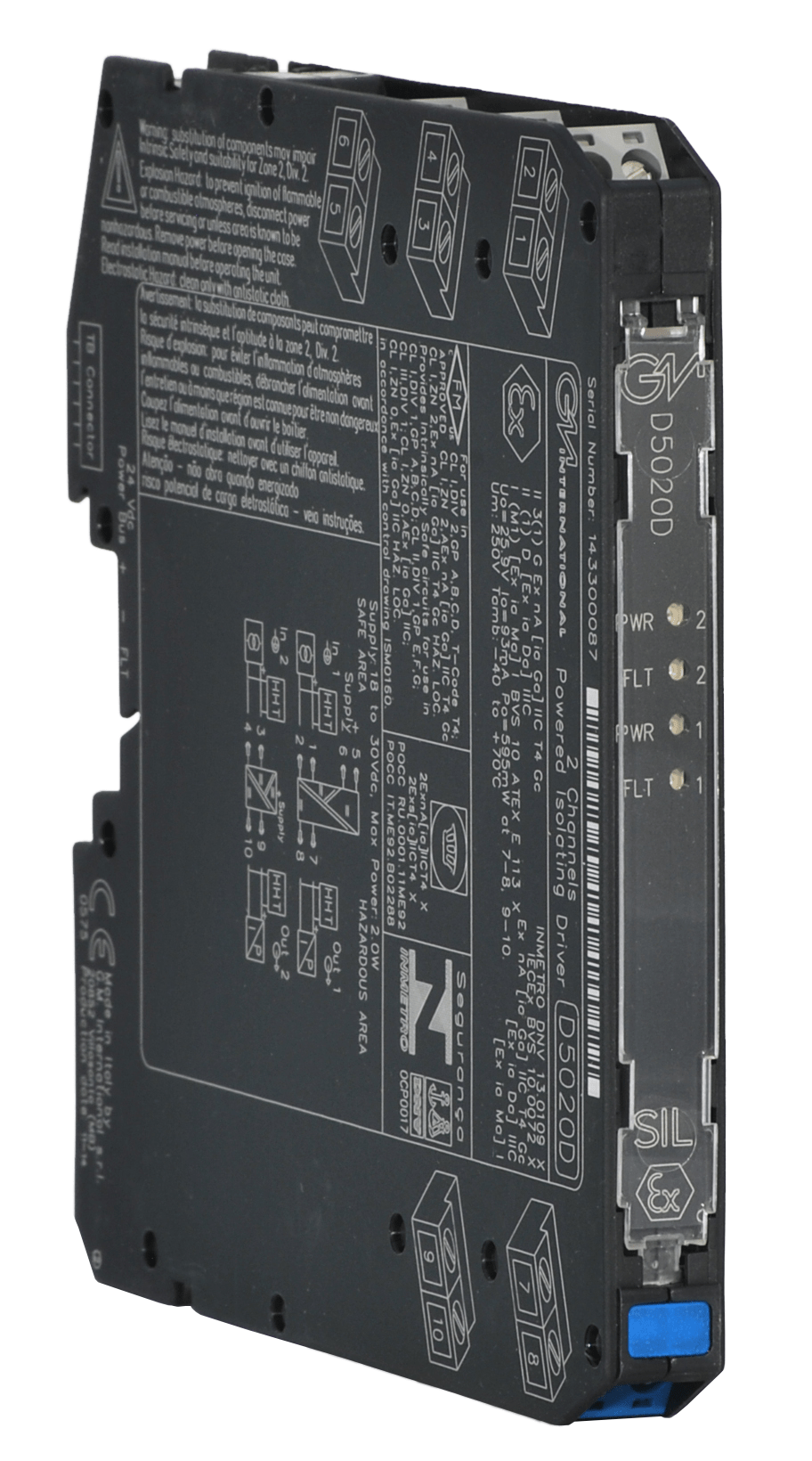

| Approvals & Certification | Monitoring Unit: (ATEX) II 1 GD EEx ia IIC T4 & Class I, II, III Division 1 Groups A-G Power Supply / Interface: (ATEX) II 1 GD [EEx ia] IIC & Class I Division 2 Groups A, B, C, D Class II Division 1 Groups E, F, G Class III Division 1 |

| Power Supply | 110V or 240V AC 50-60Hz |

| No. of Monitored Points | Up to 8 (hard wired or via clamps) |

| Monitored Resistance | Setpoint: 10 ohms (each point) |

| Status Indication | Red & green LEDs for each point |

| Interlock Contacts | One common contact output |

| Options | Multiple interlock output contacts, Ground monitoring clamps and cables for mobile equipment, Fixed monitoring leads with plug & socket connectors. |