Extronics is a globally recognized company known for the design and manufacture of equipment for hazardous areas, primarily focusing on intrinsic safety and explosion-proof solutions. Established in 1992, the company has over 30 years of experience in serving the process industries.

Extronics specializes in developing and manufacturing IECEx, ATEX, and North American certified equipment for use in hazardous areas, as well as rugged industrial products for harsh environments. They serve businesses around the world from a broad spectrum of industries such as the chemical, oil and gas, mining, and pharmaceutical sectors. Exloc is proud to offer our customers the finest products from this well-respected manufacturer of explosion-proof and intrinsically safe equipment.

Extronics’ product range includes a variety of solutions tailored for different needs, such as:

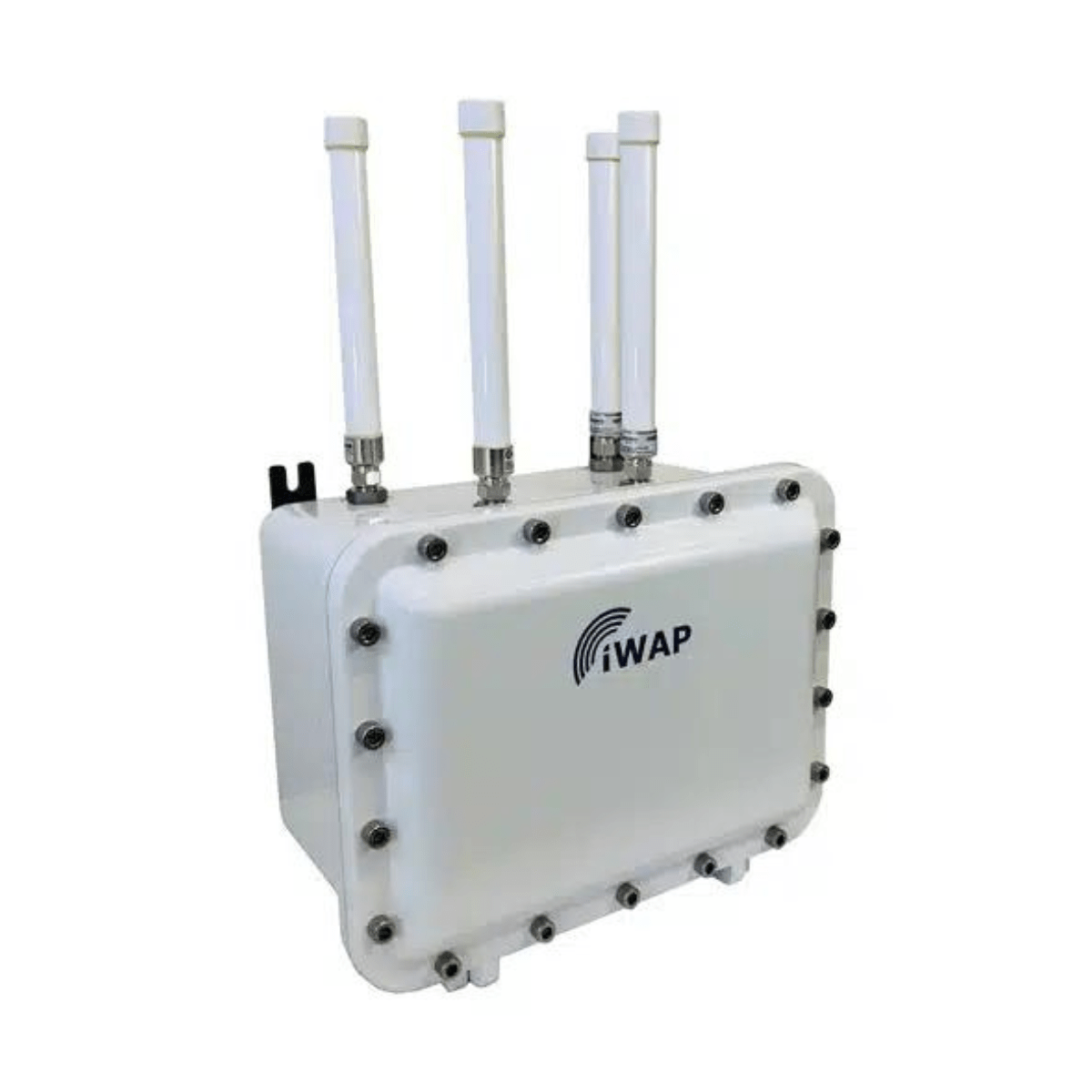

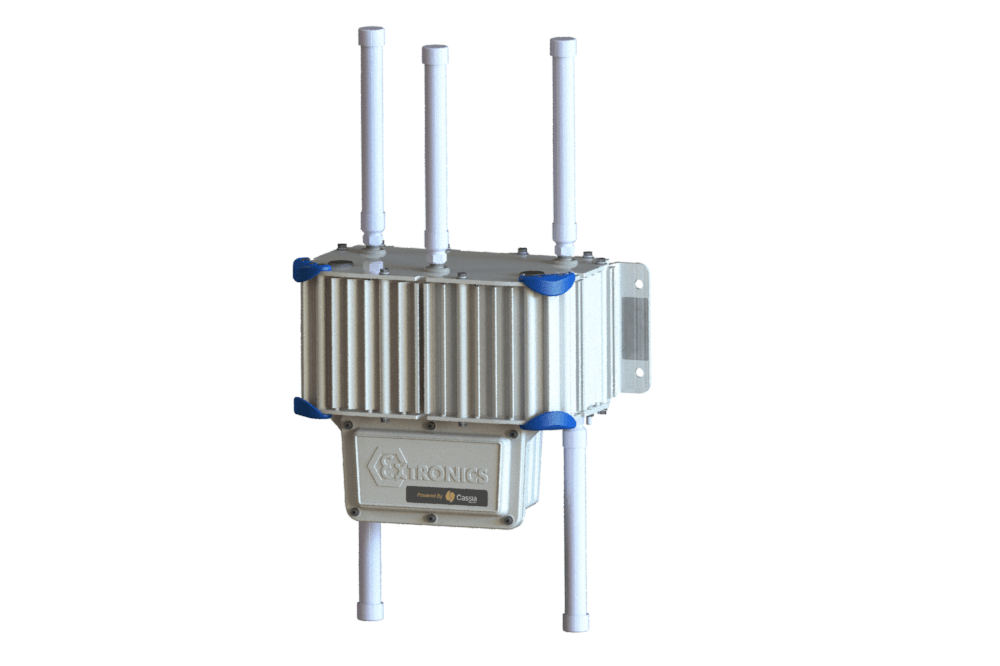

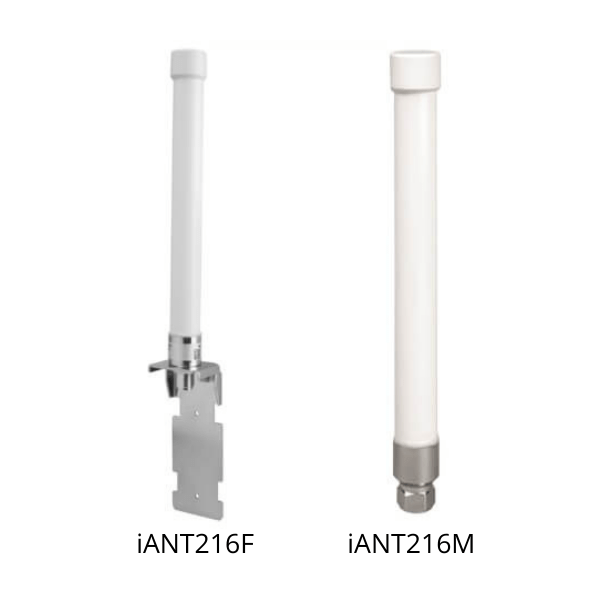

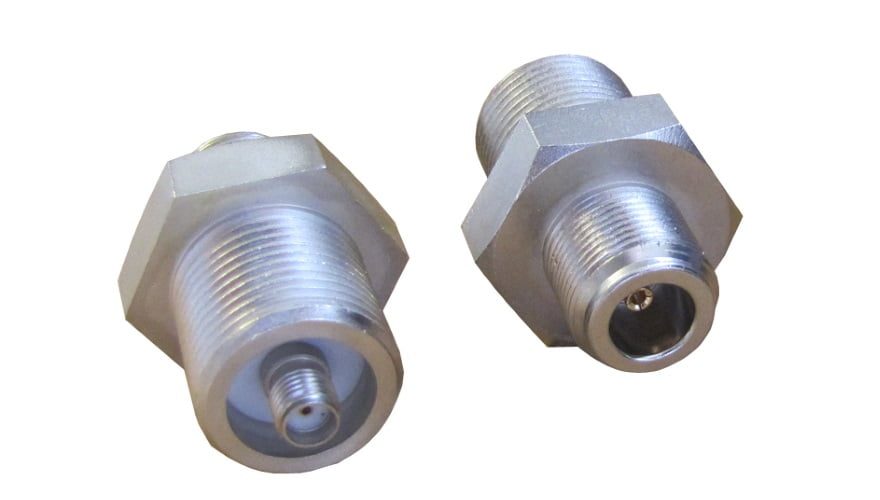

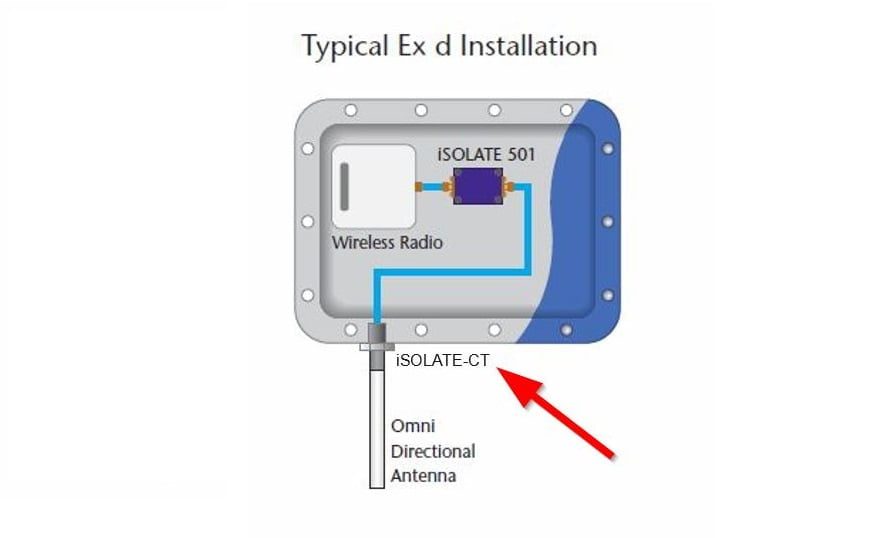

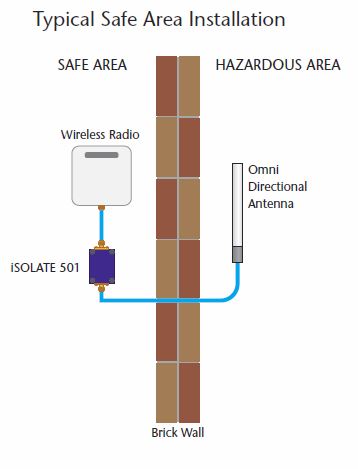

- Wireless Solutions – Extronics offers extensive wireless solutions to extend network capabilities into hazardous areas. This includes the iWAP series of wireless enclosures that are certified to ATEX, IECEx, and MET standards. These solutions are designed to be cost-effective and tailored to specific hazardous-area requirements.

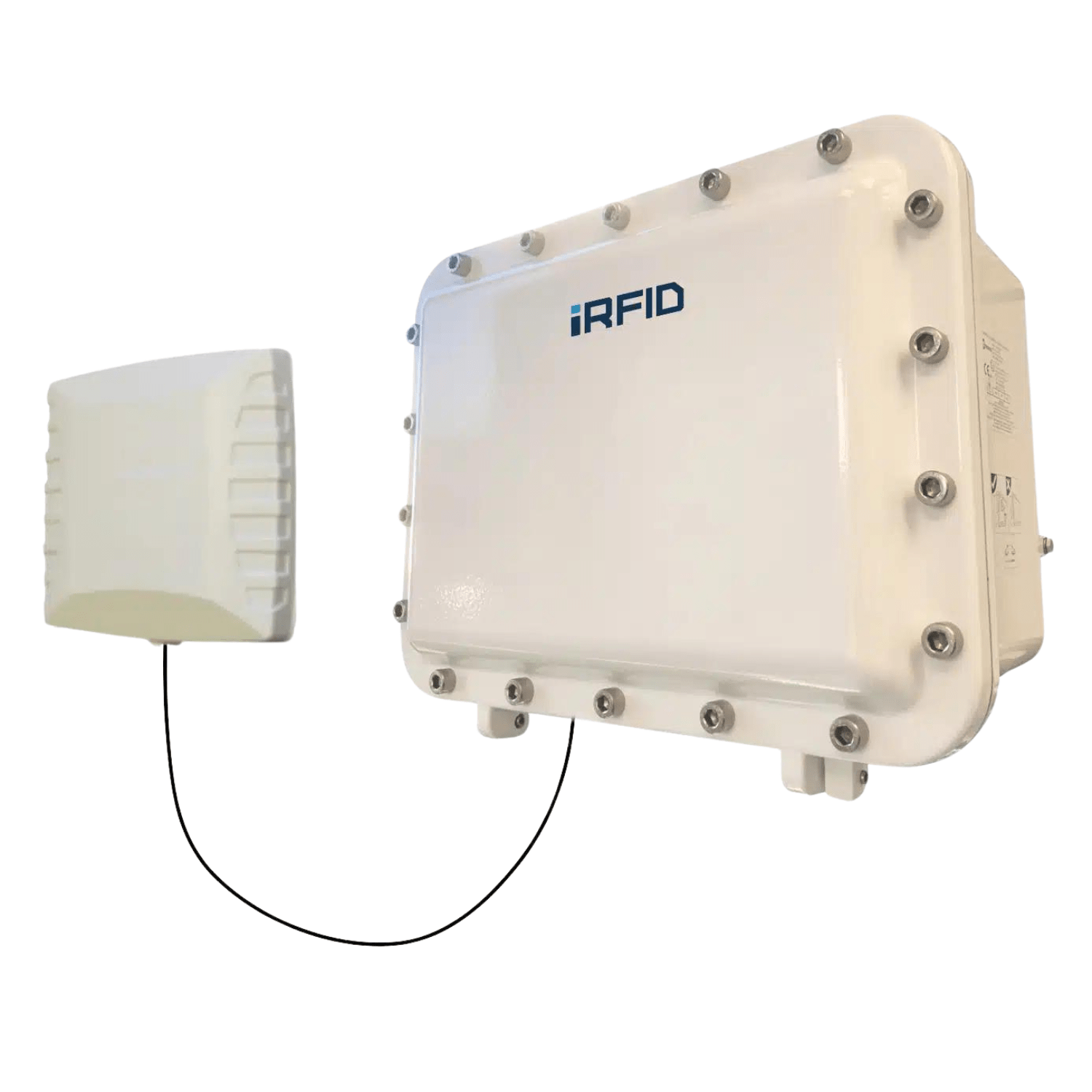

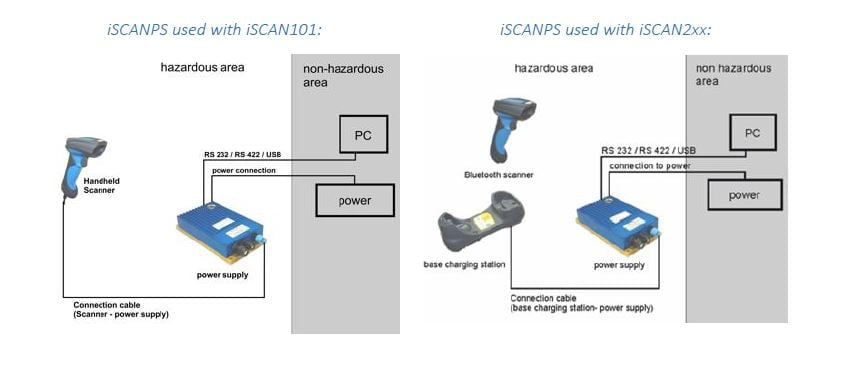

- Auto ID – Extronics provides asset management solutions in hazardous areas using passive RFID and barcode scanners. Their range of intrinsically safe UHF RFID Tag and barcode scanning solutions are designed to extend asset management into hazardous areas efficiently.

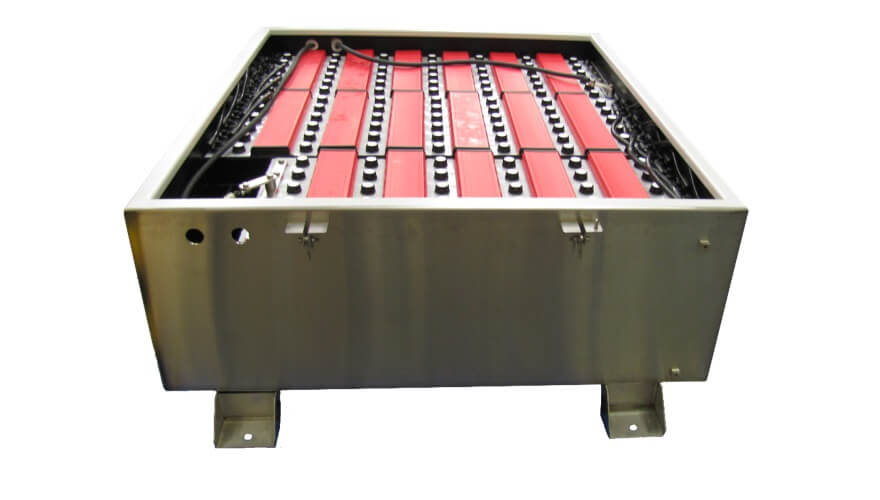

- Power Solutions – The Extronics catalog also features a range of power solutions specifically designed for hazardous areas. This includes uninterruptible power supplies, batteries, and solar solutions that cater to the specific needs of hazardous-area power requirements.

In terms of technology and innovation, Extronics collaborates with leading companies like Cisco, Aruba, and Siemens to deliver enterprise-class wireless solutions. They utilize their networking expertise to provide AeroScout Real Time Location Solutions for worker safety, accountability, and asset management. Additionally, Extronics offers asset tracking using RFID and barcode technology, which can operate standalone or be connected via Bluetooth to a smart device for an integrated solution.

Quality and compliance are pivotal to Extronics’ operations. Their management system is certified to ISO 9001:2015 and BS EN ISO/IEC 80079-34:2011 standards for the manufacture of explosive atmosphere equipment. They hold an ATEX quality module, which allows their products and solutions to be designed and manufactured in compliance with the ATEX directive 2014/34/EU, and they are also certified to design and manufacture to the IECEx standard.

Extronics’ history is marked by several significant milestones, such as making the transition from a reseller to a manufacturer in 2005, winning the Queen’s Award for Enterprise in International Trade in 2014, and introducing various innovative products like the iWAP XN3 wireless enclosure system in 2019 and the iTAG XB intrinsically safe Bluetooth tags in 2022.

Overall, Extronics demonstrates a strong commitment to safety, innovation, and customer-centric solutions in hazardous and industrial environments.

Exloc Instruments, as a distributor of Extronics products, offers a diverse range of intrinsically safe equipment suitable for hazardous environments. Our current Extronics product lineup can be viewed in this section. Feel free to contact us with any questions you may have about these or any other products offered for sale on the Exloc Instruments website.

Recently viewed

Frequently Asked Questions

What hazardous area certifications are available for Extronics wireless solutions?

Extronics wireless solutions are certified to meet global hazardous area standards. These include ATEX, IECEx, and North American Class/Division approvals. Each certification supports safe deployment in environments with gases, vapors, or combustible dusts commonly found in process industries.

Each product is designed for use in atmospheres where explosions could occur, which makes them suitable for oil and gas, chemical, and pharmaceutical sectors.

All certifications are verified through independent testing and align with strict safety protocols. This ensures safe deployment of Extronics wireless solutions in environments where flammable gases, vapors, or dust are present.

How do explosion-proof access points improve safety in industrial environments?

Explosion-proof access points allow wireless connectivity in classified zones without igniting surrounding materials. Their robust housings contain any sparks or heat generated inside the device.

This level of containment is critical in areas where standard network hardware poses a risk. By using explosion-proof access points, facilities maintain wireless communication while complying with safety regulations.

They also reduce the need for physical maintenance inside hazardous zones, which lowers risk to workers and limits operational downtime. In many facilities, these devices form the backbone of hazardous area Wi-Fi networks, enabling plant-wide mobile access to SCADA, MES, and IIoT systems.

What industries benefit most from RFID tracking systems by Extronics?

RFID tracking systems from Extronics help industries monitor the location and status of equipment, tools, and personnel. These systems are especially useful in sectors with large-scale operations and safety requirements.

Industries that commonly benefit from this include:

- Oil and gas

- Chemical processing

- Pharmaceuticals

- Utilities and power generation

RFID tracking systems improve visibility and accountability across remote or high-risk environments. They also support evacuation and muster processes by providing real-time personnel tracking.

Can Extronics provide hazardous area Wi-Fi for offshore or marine applications?

Yes. Extronics offers hazardous area Wi-Fi solutions suitable for offshore platforms, ships, and marine terminals. All equipment is rated for use in corrosive and explosive environments common to these settings.

Hazardous area Wi-Fi systems are designed to resist saltwater exposure, temperature extremes, and vibration. Products are tested for environmental durability and compliant with maritime safety standards.

Extronics wireless solutions enable stable communication offshore, supporting voice, data, and industrial IoT applications.

How does Extronics integrate industrial asset tracking with existing IT systems?

Extronics industrial asset tracking solutions work seamlessly with your current IT infrastructure. UHF RFID tags can be applied to equipment, tools, or containers and read by compatible mobile or fixed readers.

The collected tag data can be transferred into asset management systems, ERP platforms, or CMMS software. This allows for reliable identification and tracking without needing to replace existing tools or workflows.

Intrinsically safe hand held UHF RFID readers utilize bluetooth communications to connect directly with mobile devices approved for hazardous areas. Tag read data is sent in real time, supporting immediate updates to connected business systems.

Together, Extronics RFID tracking systems and barcode scanners provide seamless data capture in hazardous environments. They help extend digital visibility into areas where conventional devices cannot be used.